A continuation of last years Fibre Library parts 1 & 2 with some newly discovered books and magazines.

Disclaimer: I am not affiliated with any of the publishers, authors etc. of any books or magazines mentioned in this post. All books mentioned are my personal copies which have been purchased either new or secondhand. This list is not exhaustive, so if a book isn’t listed here it doesn’t mean it’s bad – I just haven’t discovered it yet.

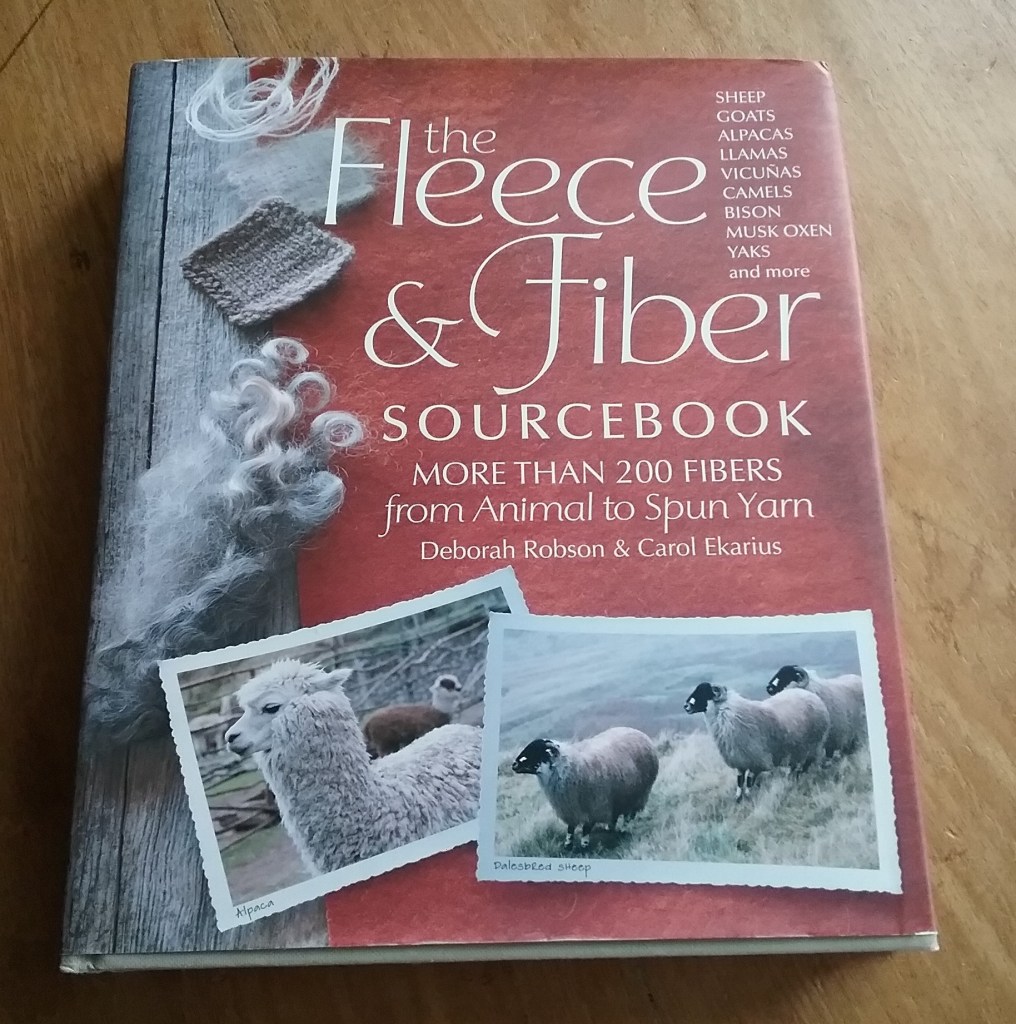

The Fleece & Fiber Source Book

Author/s: Deborah Robson & Carol Ekarius

ISBN: 9781603427111

This is an up-scaled version of The Field Guide to Fleece and is written by the same authors. It contains further information about each sheep breed alongside other animals that produce fibre (goats, alpacas, yaks etc.). Each breed is arranged in it’s group with a history, facts and figures, advice on preparation and using the wool, broken up nicely with images. Unlike the Field Guide which is pocket sized, this book is heavy, so is probably not advisable to travel with!

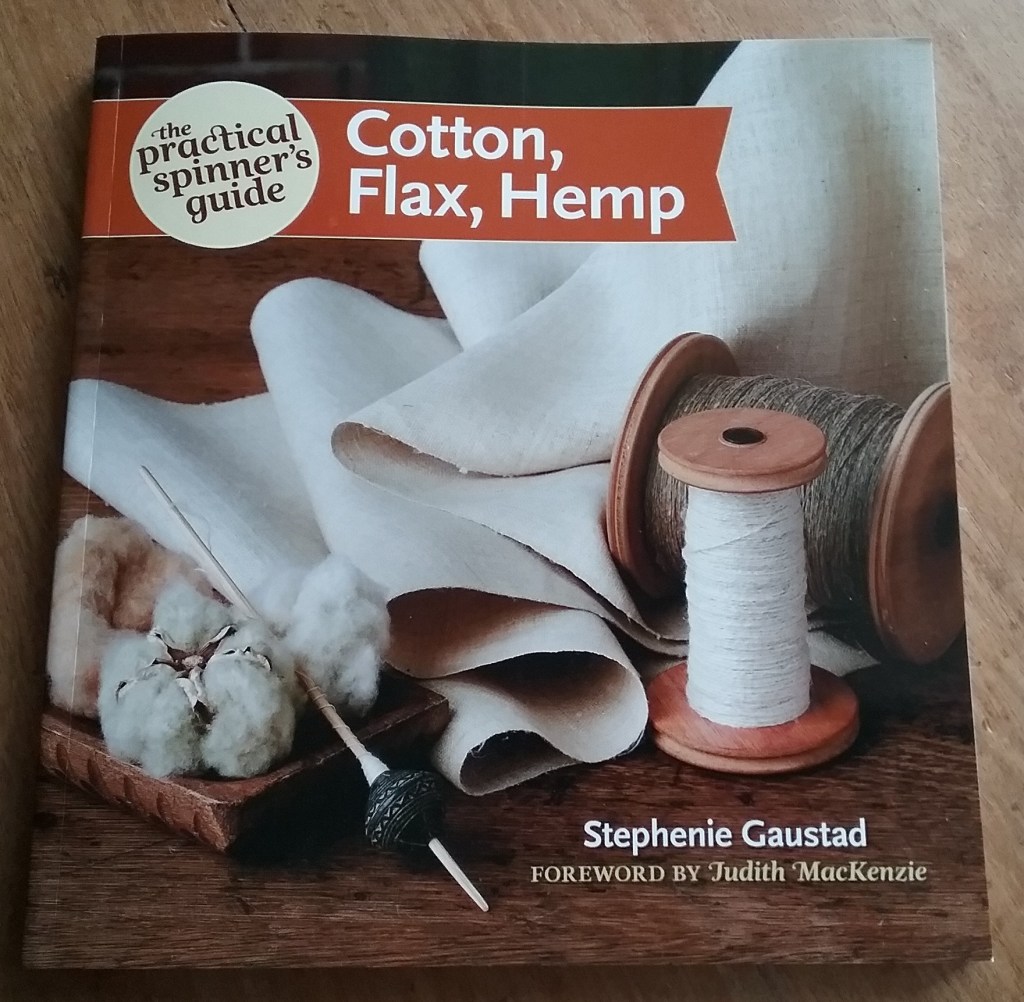

The Practical Spinners Guide: Cotton, Flax, Hemp

Author/s: Stephanie Gaustad

ISBN: 9781596686694

I have not found many books that are specific to these three fibres and working with them is quite different to working with wool. The book explains for each fibre everything from harvesting, preparation, spinning on both spindle and wheel and finishing. There are clear easy to follow diagrams and pictures with lots of hints and tips. There are also other books in the series focused on working with wool and silk, which I imagine would be written in the same manner.

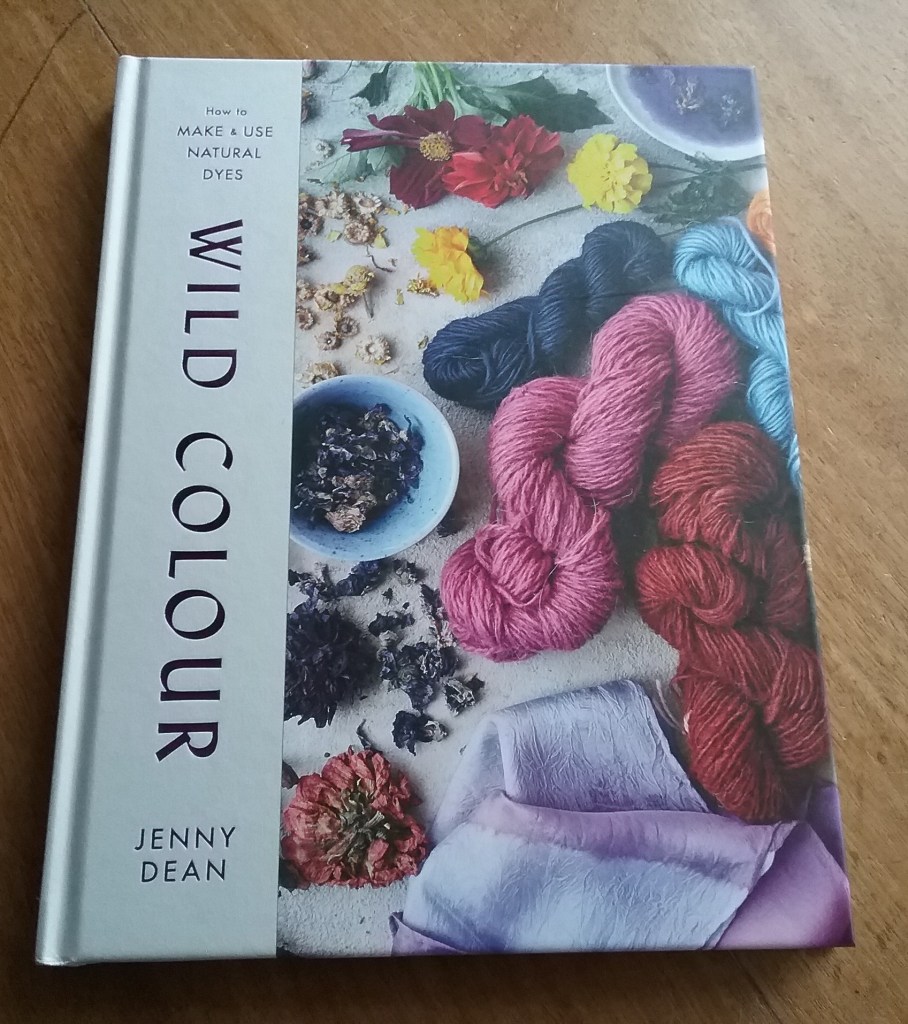

Wild Colour

Author/s: Jenny Dean

ISBN: 9781784725532

Clear and concise, this book contains a short history of natural dyeing, methods for dyeing and handy colour charts in the dye plant section showing which parts of the plant give which dyes and the effects of modifiers on these colours. It also has information on planting and harvesting dye plants, which some other books tend to emit.

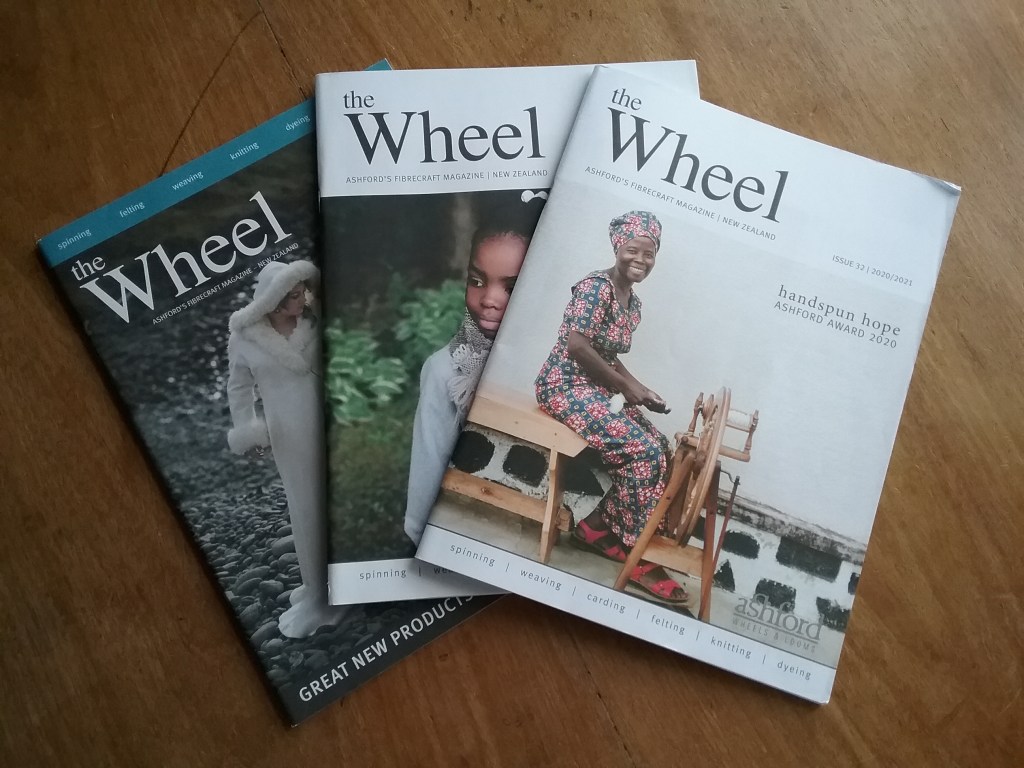

The Wheel Magazine

Author/s: Ashford Wheels & Looms

ISBN: N/A

Ashford’s annual magazine contains a variety of interesting articles written by fibre artists from all over the world. There are usually some weaving patterns, felting, knitting and spinning techniques alongside articles exploring lesser known elements of fibre craft. Although usually sourced from a subscription, Ashford also publish a non-glossy version (known as the newsprint version – pictured right) which is available free from stockists (though postage charges may apply).

Spin Off Magazine

Spin off magazine is another magazine available by subscription, but I am lucky that my local library has many issues available to borrow for free online. Like Ashford’s The Wheel it has a variety of articles from spinning to crochet, but is a bit advert heavy. Spin off do however have some interesting articles written by fibre artists on their website (image opposite is a stock image from Spin Off’s website).

The library is a good (and free!) place to look through books and some magazines can be borrowed as well. I believe many libraries now have the option of borrowing e-book/magazine copies of titles too, so you don’t even have to venture out.

If you are looking to purchase a fibre book, then please do consider supporting an independent bookshop or craft store. If you’re in the UK or America there is a website called Bookshop.org where you can purchase books online, but support an indie bookshop of your choice (I’m not affiliated – this isn’t an ad).

I would love to know if there are any fibre books that should be on my reading list, please leave me any sugestions in the comments below.

Happy Crafting!