Happy Wovember! It’s that time of year again when we fibre enthusiasts spend the month highlighting the importance of wool. This year I have not had as much time to make and research my usual posts, but as Wovember draws attention to the importance of correctly describing articles made from wool (i.e. not labelling something made from acrylic fibre as ‘woollen’) I thought it would be a brilliant opportunity to share some sources of information on the labelling of wool products and the impact of fast fashion. I am in no way affiliated with any of the companies mentioned and have provided references to all sources used. Do go forth and explore.

Week 4 – Making textiles last longer

The easiest way reduce the environmental impact of our clothes and textiles is to make them last longer regardless of fibre content. It’s good to start by checking how well made an item is before you buy it; if the stitching looks flimsy, the fabric looks thin or is already pilled/damaged then the likelihood of it lasting a long time is slim. Buying items second-hand or making your own can also be a cost effective way of getting a well made item.

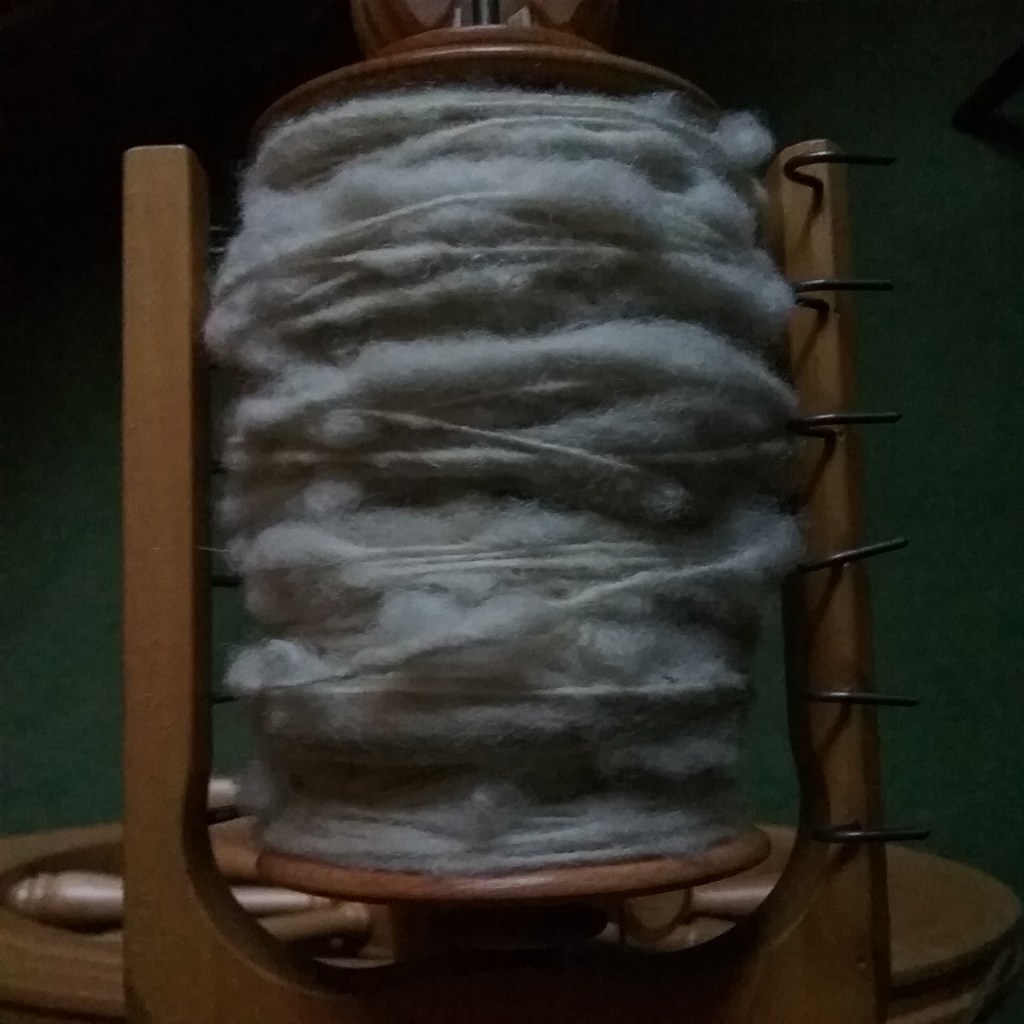

The most common care procedure for clothing and textiles is washing. Washing synthetic fibres releases microplastic particles into the water system which harms marine life and can enter the food chain. Natural fibres don’t shed these harmful particles, but are often considered difficult to wash; the worry with wool is usually shrinkage or felting. The willingness of wool to felt depends on the fleece, the temperature of the water and the amount of handling it has. Wool is hardier than you think though and I have never had a problem washing it (though I do prefer to wash my handmade items by hand). Newly handwoven fabric should allow for some shrinkage (or fulling) in the first wash as the fibres are released after being tensioned on the loom, but after this they should not shrink further. As wool has natural elasticity, textiles can also be shaped while they are drying (for example; lace knitted shawls are often pinned into shape as they dry.). There are lots of useful sources regarding washing wool clothing, but The Woolmark Company have a concise section on their website with accompanying videos: https://www.woolmark.com/care/can-i-wash-wool-in-the-washing-machine/

Then there is repair. There are a multitude of repairs a textile can need and numerous ways to go about this, from delicate invisible repairs to a visible repair that stands out and makes a garment one of a kind. I find my most common repairs are holes. These can be patched, but darning can be useful when you want to try and match the weave of the fabric. I was particularly excited to discover that darning is really the same as weaving, only instead of a putting a warp on a loom you use the fabric. I’ve linked some useful resources below explaining different methods of textile repair, and have also linked my own mini tutorial for weaving on a pin loom (as it is a similar process).

- Weaving on a pin loom – My mini tutorial

- Darning a Hole – Youtube video

- Ladder stitching a hole – Youtube Video

- Invisible Mend for Knitted Garments – Youtube Video

- Various Mending Methods – Woolmark Company website

Happy Wovember!

Further Reading