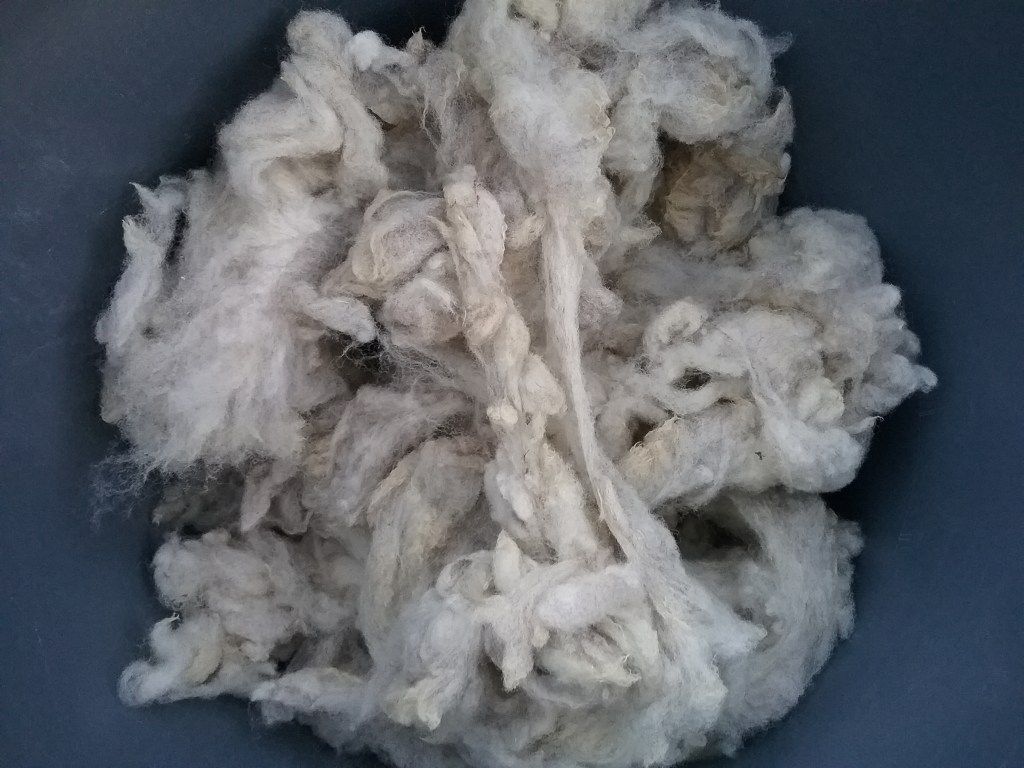

The Fleece

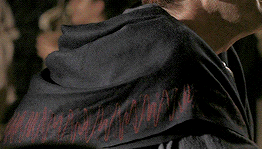

I bought this Hampshire Down fleece via eBay during lockdown from Our Welsh Farm’s Ram. The fleece was clean and had very little VM and there were very few areas of significant kemp. The fleece had varied colour palette, moving between oatmeal, white, grey and black. Although soft, it was slightly coarser than other fleeces I’ve worked with, but mature rams do tend to have coarser fleece than ewes. Since I’ve been making lots of next to skin clothing and accessories from my other fleeces, I think the colours in this need to be shown off in outerwear or homeware.

Washing

This fleece was washed in my suint bath (and was quite challenging to lift out when wet as I had forgotten that rams are larger than ewes, so the fleece was much heavier when wet!). The suint bath removed most of the grease and in the absence of a lingering suint smell, I decided to forgo a wash in detergent.

Picking & Carding

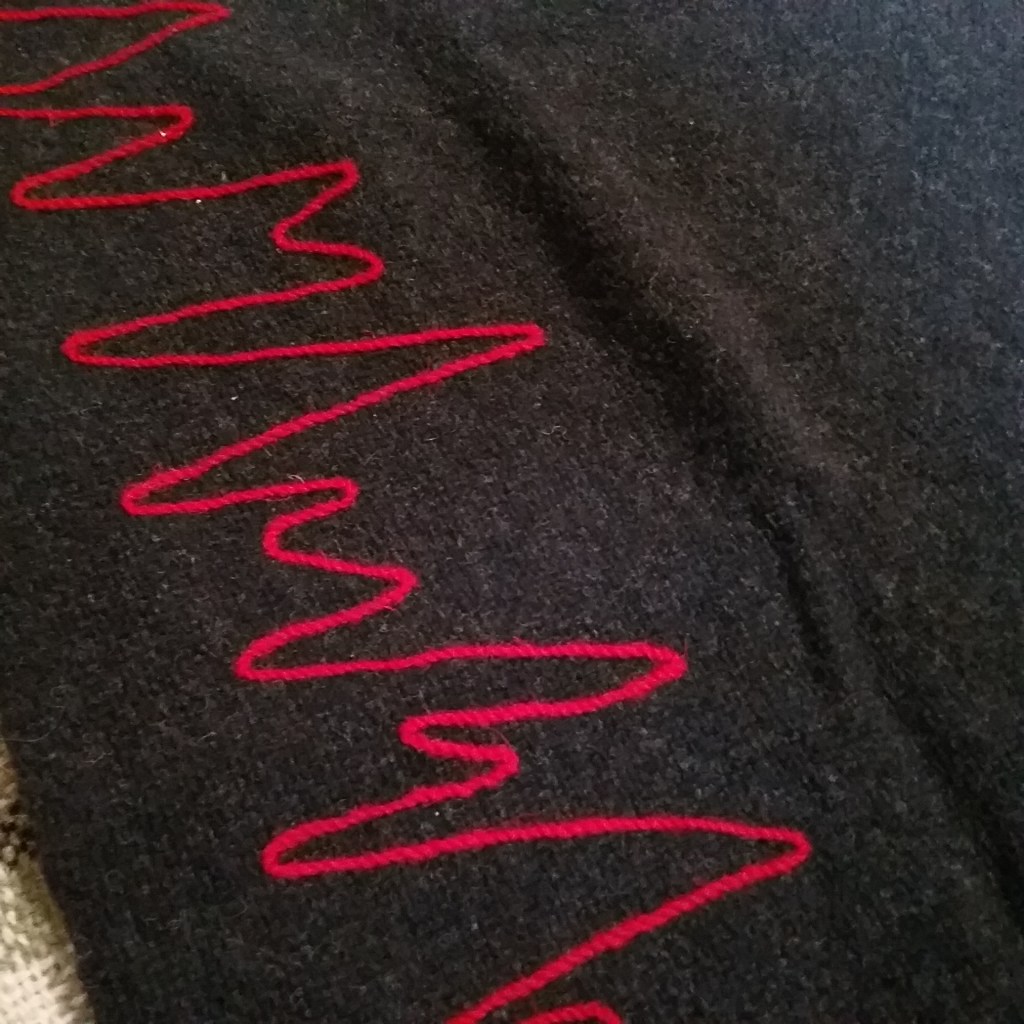

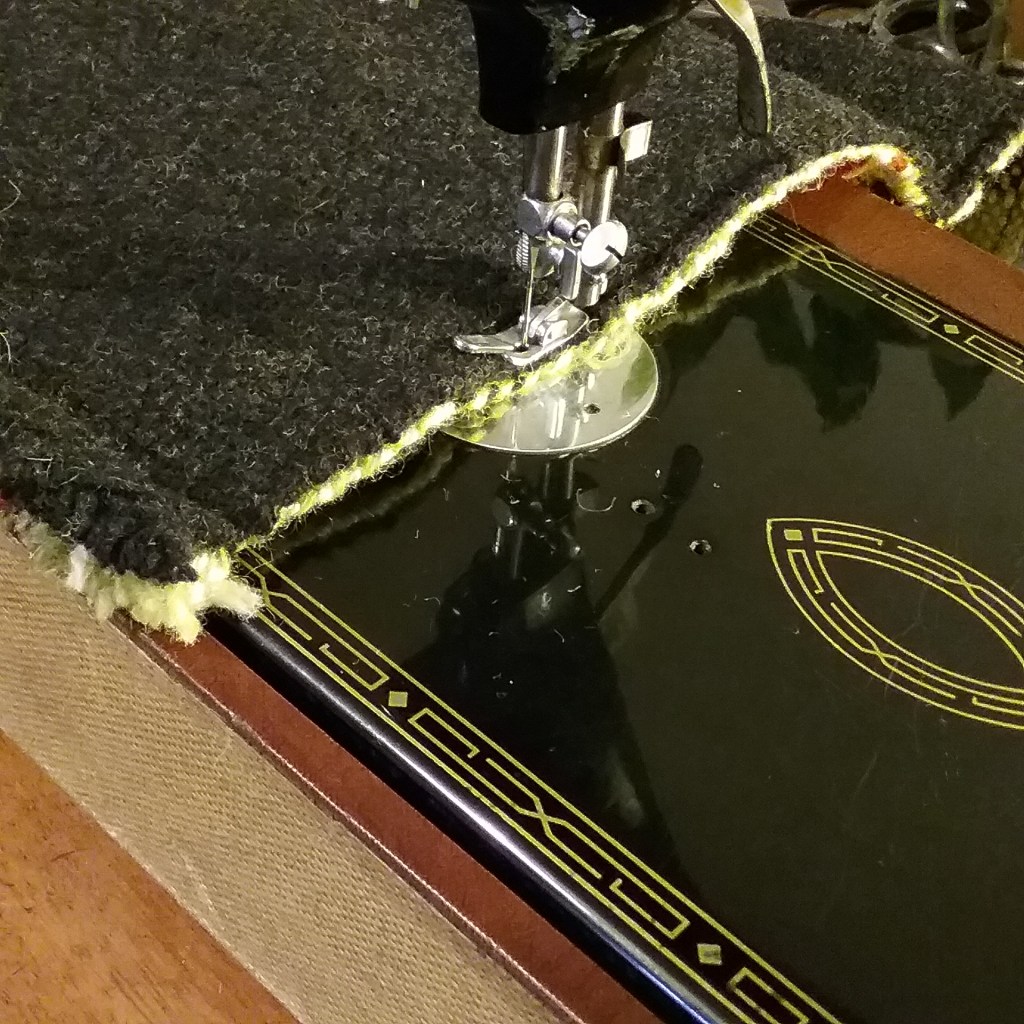

After washing and drying I noticed the fleece was a little tangled and still seemed to have quite a bit of dust. I decided to put it through my wool picker and open up the fibres to make carding easier and remove most of the dust. This worked perfectly, although I did find that the shorter staple fibres needed removing from the teeth at times.

Due to the short fibres, carding was the sensible option. I found hand carding was easiest using my flat carders rather than the curved and most of the time the fibres only needed two passes to align. I did put some through the drum carder, but found it needed more passes than doing it by hand and I found I had more control over the shorter fibres spinning from rolags rather than batts. Hand carding also gave me more control over removing any left over VM and nepps.

I had a conversation with a friend recently who said how much they enjoyed watching crafters work and that I ought to film myself working. Thinking this quite a good idea, particularly in demonstrating what I write about, I took the opportunity during tour de fleece to do just that, so for those interested please find below some hand carding.

(I don’t have a very professional set up so excuse the harsher audio and any loss of focus – it’s best viewed in 1080p HD on the Youtube Settings)

As always, let me know if you have any tips/advice in the comments below and let me know if you would like more video content in my future posts.

Happy Crafting!

Further Reading about Hampshire Down:

- Breed Society Website – www.hampshiredown.org.uk

- British Sheep & Wool by the British Wool Marketing Board – ISBN 9780904969108

- The Field Guide to Fleece by Deborah Robson & Carol Ekarius – ISBN 9781612121789

- The Fleece & Fiber Sourcebook by Deborah Robson & Carol Ekarius – ISBN 9781603427111