One of the lesser discussed parts of having items made from natural fibre is the pests. There are a number bugs and beetles that enjoy munching on keratin fibres (they’re made of protein after all), and unfortunately they don’t care about what or where they eat (and acrylic fibres are at no less at risk of being munched). But this post isn’t about how to repel pests – it’s about dealing with the damage they’ve left behind.

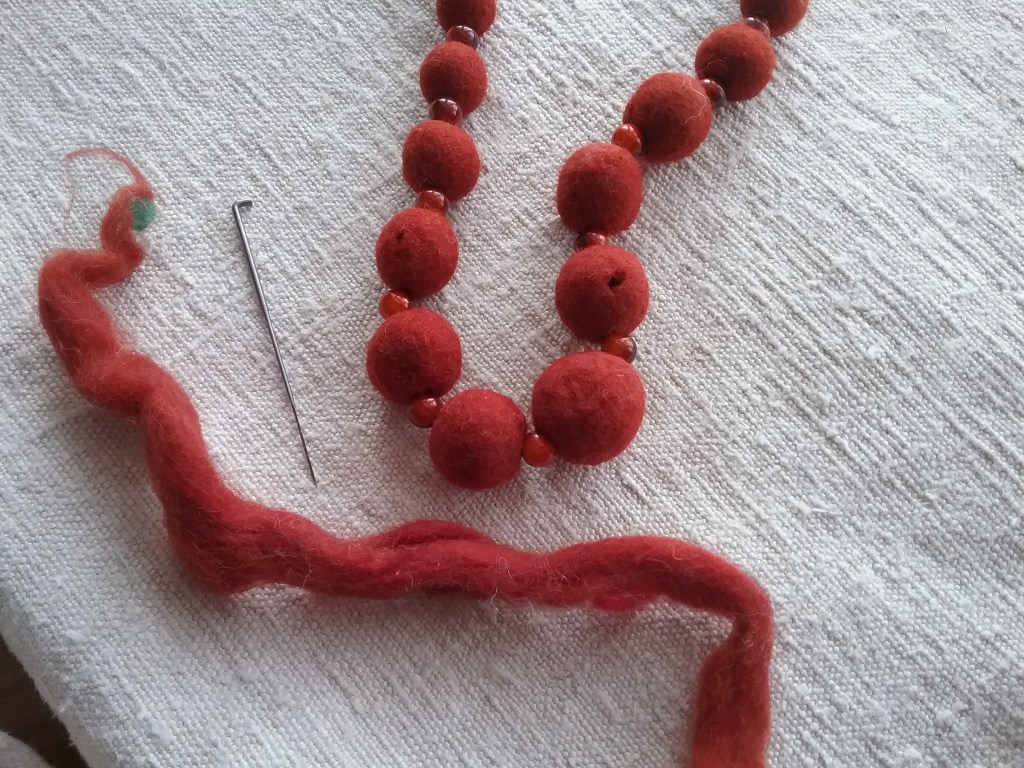

This felted necklace belongs to my mum, and had been munched on. I’ve read that some people throw away items damaged by beasties, but this seems a shame when the damage could be repaired. To make sure there was no chance of further infestation, the necklace was washed in hot soapy water (since the beads are felt and glass it didn’t take any harm), and once dry, it was sealed in a bag for a while before moving onto the repair.

The two holes were quite small and as luck would have it I found some fibre of a matching colour in my stash. I decided I would try needle felting the fibre into the holes; this was a fairly straightforward process and worked a treat, however I learnt that unlike needle felting a whole object, wet felted beads are surprisingly hard to felt into, which meant I needed to work slowly and gradually coax the fibre into the hole (a fiddly process that meant didn’t leave me enough hands to take a photo). I also managed to break two felting needles as they are not designed to bend and it was difficult not to move the bead or needle when working (I’m also very new to needle felting so it is also possible I was using too delicate a needle!).

The finished repair isn’t too visible – there are a few small needle marks where I can tell I’ve repaired it, but happily it doesn’t really show.

Happy Repairing!